Get Brampton commercial cleaning and sanitation professionals who follow CSA, WHMIS, and Peel Public Health. We provide SOPs, SDS access, batch/lot traceability, calibrated dilution logs, and documented verification. We validate disinfection with ATP/fluorescence, guarantee dwell times, and utilize ECOLOGO/Green Seal, DIN/EPA-registered products. Teams operate off-peak with access controls, color-coded tools, and chain-of-custody for disinfectants. Verifiable documentation, CAPA workflows, and sector-specific protocols (office, retail, healthcare, industrial) are included. Learn how we minimize interference while enhancing adherence.

Key Takeaways

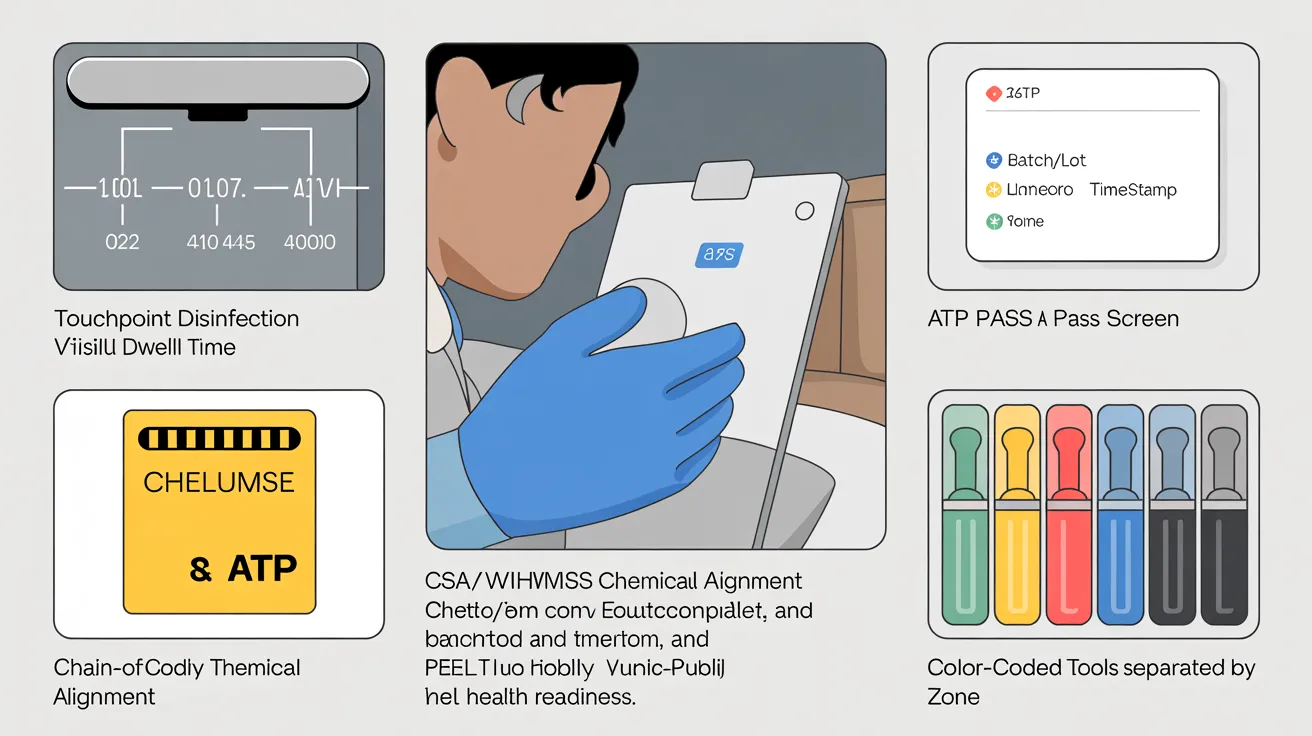

- Comprehensive SOPs following CSA, WHMIS, and Peel Public Health guidelines with fully auditable documentation featuring lot tracking, SDS libraries, and verified service timestamps.

- Risk-based sanitization process: incorporating comprehensive touchpoint mapping, EPA-approved cleaning solutions, validated contact duration, ATP and fluorescence validation, and regular third‑party microbiological analysis.

- Operational excellence: employing after-hours operations, small specialized teams, access control, documented handling for chemicals, and calibrated dispensing with service records.

- Environmental leadership: ECOLOGO and Green Seal certified products, automated dilution technology, microfiber cleaning systems, thorough waste evaluations, and ISO 14001-aligned diversion metrics.

- Comprehensive quality assurance featuring management reviews, corrective action procedures, staff development tracking, and regulatory reports tailored for municipal requirements, insurance standards, and regulatory bodies.

Why Professional Cleaning Matters for Brampton Businesses

Although routine tidying maintains surface appearances, professional cleaning services ensure your Brampton premises meets safety, health, and compliance protocols. You require established protocols conforming to local requirements, validated cleaning solutions, and precision-tuned equipment to minimize contamination risks and liability. Trained professionals employ proven operational procedures, color-specific cleaning implements, and controlled contact duration to guarantee complete sanitization and debris removal without compromising surface integrity.

You can expect risk assessments that map movement flows, interaction points, and air system influence, then set measurable frequencies and QA checks. Weather-related aspects are important: cold weather necessitates doorway washing and matting upkeep; summer humidity requires humidity management and mold mitigation; transitional seasons introduce pollen and debris that necessitate enhanced filtration and high-dusting. Thorough logs, SDS accessibility, and waste handling procedures facilitate reviews and verify regulatory compliance.

Industries We Serve: Offices, Retail, Healthcare, and Industrial

Your facility demands sanitation procedures that align with office and retail requirements-high-contact surface sanitization, floor care programs, and waste segregation-while following local health and safety bylaws. For healthcare, it's essential to have CSA- and IPAC-compliant procedures, EPA-approved sanitizing agents, verified contact duration, and tracking documentation for biohazard handling. In industrial settings, you require WHMIS/GHS labeling, equipment isolation protocols, HEPA and hazardous dust control, and inspection-ready protocols.

Commercial Space Protocols

When operations span across offices, retail floors, healthcare facilities, and industrial sites, sanitation procedures need to comply with industry-specific requirements and measurable quality standards. Within office and retail spaces, you'll need to document frequency, method, and verification for each zone. Utilize floor plans to chart high-traffic areas, contact points, and surface requirements, and organize duties according to risk levels. Specify appropriate cleaning agents, mixing proportions, and contact duration; record safety documentation access points and solution dispenser settings.

Standardize staff guidelines for: glove changes across zones, wire control, silent operation protocols, and warning displays for accident avoidance. Set up a color-based organization for equipment to eliminate cross-zone contamination in restrooms, break rooms, and public spaces. Schedule systematic vacuum maintenance, microfiber system updates, and disposal segregation. Assess performance using contamination sampling, maintenance records, and remediation processes aligned with inspection standards and client service agreements.

Industrial and Healthcare Standards

Because of healthcare and industrial facilities maintain increased risk profiles, we put in place proven procedures that meet regulations and endure audit scrutiny. You get site-specific Standard Operating Procedures aligned with CSA, Public Health Ontario, and OSHA/WHMIS requirements. We implement color-coded tools, closed-loop chemical dilution, and barcode-logged activities to ensure accountability, infection control, and contamination avoidance.

Throughout our medical facilities, we follow Spaulding classifications, conduct terminal cleaning, and use EPA-registered disinfectants with specified wet contact times. We verify effectiveness through bioluminescence monitoring and detailed audit checklists. Designated sharps zones maintain puncture-resistant waste handling and comprehensive chain-of-custody tracking.

In industrial settings, we coordinate safety lockout protocols, dust hazard mitigation, and non-sparking tool implementation. Floor surfaces receive degreasing treatment with slip-coefficient testing. We perform meter calibration, maintain SDS documentation, deliver hazard communication training, and produce compliance records aligned with your audit protocols and insurer requirements.

Advanced Disinfection Protocols for High-Touch Areas

Though regular cleaning eliminates visible dirt, sophisticated disinfection protocols target microbial populations on high-touch surfaces with validated, measurable methods. You'll start with touchpoint assessment to catalog shared equipment, door fixtures, handrails, light switches, faucets, elevator controls, and payment terminals. Assign risk levels, set dwell times per EPA-registered disinfectant, and document material compatibility to prevent surface deterioration. Establish sequence: clean first, apply product, ensure proper contact time, and confirm.

Utilize electrostatic spraying for complex geometries and uniform wrap-around coverage; adjust nozzles, validate droplet size, and control pass speed. Perform rapid hygiene monitoring or fluorescence markers for instant quality confirmation, and plan periodic third-party microbiological swabs for outcome validation. Instruct staff on safety equipment protocols, product documentation review, and lot tracking. Log batch numbers, time records, and operator IDs for compliance preparation and problem investigation.

Eco-Friendly Products and Sustainable Practices

You'll select eco-friendly cleaning products that meet ECOLOGO or Green Seal standards and conform to WHMIS and SDS protocols. You'll establish waste minimization approaches, including microfiber technology, dilution management, reusable dispenser options, and source-separated recycling as per Brampton and Ontario regulations. You'll validate performance with VOC limits, biodegradability standards, and periodic assessments to record compliance and ongoing improvement.

Environmentally-Certified Cleaning Agents

Establish a higher compliance benchmark by requiring green-certified cleaning solutions that comply with respected standards such as ECOLOGO (UL 2792/2795), Green Seal (GS-37/GS-53), or EPA Safer Choice. In your eco certifications summary, list the item name, certification ID, dilution ratios, pH range, VOC content, and SDS references. Require third-party verification on containers and verify listings in each certifier's online registry.

Select cleaning products suitable for microfiber applications, automatic scrubbers, and contact point procedures. Choose surfactant systems with rapid biodegradation, non-NPE formations, and minimal aquatic impact scores. Determine residue limits to enhance allergen reduction on heavily accessed zones and in air quality-sensitive areas. Implement precise dosing mechanisms to prevent overuse and ensure ppm accuracy. Train staff on dwell times for sanitizing options conforming to Safer Choice's partner criteria. Conduct quarterly reviews, sample-test residues, and track exceptions with remedial measures.

Strategies for Minimizing Waste

While upholding strict hygiene standards, establish waste reduction by implementing sustainable and reusable systems across sites. Begin by conducting Waste audits to quantify material streams by volume, contamination levels, and disposal expenses per department. Use findings to select long-lasting dispensers, bulk chemicals, microfiber solutions with monitored washing and color-designated containers. Enforce vendor return for packaging and pallet recovery.

Establish compost programs for organic materials generated in food preparation areas, ensuring that disposal liners conform to ASTM D6400 and collection services will take them. Optimize collection timing using bin fill-level measurements to eliminate overflow and pest concerns. Provide staff training with operational guidelines, clear signage, and quarterly updates. Monitor performance metrics: recycling effectiveness, per-person waste generation, and compliance issues. Maintain documentation to satisfy city requirements and ISO 14001 criteria.

Adaptable Scheduling for Reduced Downtime

In line with business operations, flexible scheduling ensures cleaning takes place outside high-traffic times to eliminate service disruptions and revenue losses. You establish precise maintenance timeframes, enhanced through after-hours coordination, so teams operate when foot traffic and production are at their lowest. We analyze check here your operating calendar, blackout periods, and statutory holidays, then align work procedures to eliminate overlap with shipments, inspections, and upkeep.

To ensure smooth operations, we employ staggered shifts and specialized teams with position-based guidelines, time-tracked assignments, and quality standards. Personnel adhere to noise, odor, and illumination restrictions, and apply fast-acting formulations to reduce processing times. Entry control, key tracking, and record-keeping processes maintain oversight. We systematically track service details, problem resolution, and safety reporting to meet compliance requirements, labor agreements, and community standards while maintaining productivity.

Deep Cleaning vs. Regular Maintenance: What to Know

Since operational risk and compliance requirements vary by task, it's essential to maintain a clear separation between daily maintenance (scheduled cleaning to maintain cleanliness baselines) and thorough sanitization (periodic thorough cleaning that restores hard-to-reach and high-risk areas). You should allocate regular cleaning to frequently contacted areas, restrooms, floors, and common tools using validated detergents, microfiber tools, and dwell-time verified antimicrobial agents. You must record schedules, safety gear, methods, and pass/fail outcomes.

Plan thorough sanitization as scheduled maintenance based on hazard mapping: critical areas including ceilings, HVAC systems, grout lines, equipment spaces, drains, and porous surfaces. Utilize bioluminescence or UV markers to validate pre/post results, transition to HEPA filtration, scale removers, and steam cleaning where biological contamination is possible. Define standard procedures, color systems, and equipment separation to reduce cross-contamination. Record observations, remedial measures, and follow-up schedules to ensure compliance.

Health and Safety Standards Compliance

Your maintenance plan will only be effective if it aligns with statutory and industry requirements, so connect every task to specific standards and record proof of conformity. Map each surface, chemical, and method to established safety and health guidelines. Keep SDS libraries, dilution logs, lot tracking, and measurement verification logs. Train staff on PPE selection, donning/doffing, and exposure response. Install color-coded tools and closed-loop chemical systems to prevent cross-contamination. Plan internal audits, keep checklists, photos, and corrective actions to ensure inspection readiness. Review regulatory updates from Peel Public Health and provincial authorities; modify SOPs, signage, and risk assessments accordingly. Verify disinfectant contact times with ATP testing and document results. Manage access to storage, mark secondary containers, and maintain ventilation checks with documented maintenance.

Custom Solutions for Event Aftermath and Peak Traffic Periods

Despite compressed maintenance timeframes during peak periods, you require fast, regulation-adherent sanitization that maintains hygiene standards without impacting daily operations. You receive strategic mass-gathering cleanup methods that systematically partition zones, analyze cleaning requirements, and deploy rapid-cure solutions verified against ASTM and Health Canada guidelines. Our team conducts complete sterilization of common contact points including rails, seats, and concessions using DIN-registered agents with specified contact times.

When treating floor surfaces, we apply slip-resistance-preserving detergents, auto-scrub paths, and microfiber cleaning processes to prevent re-soiling. Waste management is conducted per municipal bylaw, with sharps, glass, and organics managed via labeled containers and manifesting. Post event odorcontrol utilizes contamination extraction, biological treatments, and MERV 13-18 air filtration to restore IAQ benchmarks. Restroom turnarounds consists of descaling, grout cleaning, and restocking based on occupancy projections.

Skilled Professionals and Quality Management Systems

Such large-scale protocols are only effective when certified professionals execute them under a documented QA framework. You count on trained technicians who comply with SOPs mapped to CSA, WHMIS, and manufacturer guidelines. Each professional performs fundamental and periodic skill assessment on chemical interaction, dwell times, microfiber sequencing, and ATP verification. You mandate chain-of-custody documentation for disinfectants, calibrated meters, and color-designated area controls to avoid cross-contamination.

The quality management system maintains a closed-loop structure. Team leaders execute comprehensive audits with established protocols, testing frequently contacted areas through ATP measurements and visual inspections. Quality deviations initiate improvement measures, detailed issue analysis, and competency development. Service verification includes time documentation, with photo documentation stored in compliance records for performance tracking and examination. Quarterly drills, PPE fit testing, and competency update sessions maintain measurable and up-to-date competencies.

Finding the Ideal Cleaning Company in Brampton

While choosing a Brampton cleaning company, consider more than cost and examine proven conformity, employee protocols, and operational controls. Verify WSIB coverage and liability protection levels, along with industry certifications (such as ISSA, GBAC). Request standard operating procedures, cleaning product lists with SDS, and equipment service documentation. Ensure security clearance checks, vaccine protocols where applicable, and proper supervisor-to-staff ratios. Confirm certified education on WHMIS, exposure control procedures, and regional guidelines, including waste disposal and medical waste management.

Evaluate quality assurance frameworks including regular audits, environmental monitoring protocols, and improvement tracking systems with recorded remediation steps. Require key indicator tracking (service intervals, defect rates) and issue management protocols. Match specifications with financial constraints through measurable frequencies, work schedules, and operational standards. Confirm environmental compliance proof and air handling requirements. Implement backup procedures for health incidents, resource shortages, and after-hours access control.

Common Questions and Answers

Contract Durations and Cancellation Guidelines for Cleaning Services

Standard cleaning contracts usually operate on month-to-month, 6-month, or 12-month terms. These contracts include details about scope, KPIs, renewal options, and rate changes. Termination provisions generally specify 30-60 days' notice for standard cancellation, while direct termination is allowed for serious issues like safety violations, expired insurance, or nonperformance issues. Early termination typically involves cancellation charges. Verify that notice procedures (mail or email), correction windows (5-15 days), and financial settlement terms are properly outlined to maintain compliance.

Can I Get Emergency Spill or Biohazard Cleanup Outside Regular Hours?

Indeed - we deliver after hours services for biohazard and spill emergencies. Like a red alarm cutting through midnight silence, we'll dispatch a rapid response unit within 60-90 minutes. Technicians arrive in PPE, set up biohazard containment, isolate HVAC if required, and follow OSHA, WHMIS, and local public health protocols. We maintain chain-of-custody for waste, perform ATP verification, and provide incident reports. You authorize by phone; we mobilize immediately and bill under emergency service rates.

What Vetting and Insurance Protocols Are in Place for Our On-Site Team?

Our technicians are thoroughly vetted via a multi-stage screening process. We conduct complete national and local criminal checks, authenticate identity, and confirm right-to-work eligibility. We require two professional references while we validate employment history and work record. Drug tests are administered as specified by client SOPs. Everyone must finish required safety education, WHMIS/OSHA certification, bloodborne pathogens education, and site-specific instruction. We conduct annual background re-checks for every technician. All personnel are covered by general liability, pollution, and workers' compensation insurance; all certificates and endorsements are provided upon request.

Is Service Integration Possible With Building Security and Access Control?

Absolutely. You have the ability to align operations with your building's access management and security measures through specified integration frameworks and comprehensive credential management. You'll set up time-bound badges, access-level authorizations, and geofenced access. We'll enable system integrations via API or OSDP, audit-log syncing, and guest access procedures. You'll enforce MFA, restricted privilege policies, and background-verified user provisioning. We'll establish standard operating procedures, incident response, and instantly terminate access upon scope changes. You'll get compliance documentation and access exception alerts.

How Are Cleaning Tasks and Service Performance Tracked Through Reports and Dashboards?

Get precise control through a KPIs dashboard and mobile logs providing clear, consistent compliance monitoring. The system displays real-time updates, including check-in times, location data and service level compliance. The system allows filtering of data by zone, shift, or technician and create thorough documentation. The platform enables monitoring of resource utilization and conformity checking. Information security is maintained via user-specific permissions and enterprise-grade encryption, while API integration enables comprehensive business intelligence analysis.

In Summary

You're not simply employing cleaning staff-you're securing a meticulous enhancement for your property's wellbeing. With calibrated disinfection for high-traffic surfaces, environmentally approved solutions, and inspection-ready records, you'll achieve compliance with precision. Adaptable timing ensures smooth operations, while special event recovery solutions eliminate event remnants. Skilled professionals, detailed protocols, and quality assurance checks guarantee uniformity. Choose a Brampton provider that validates conformity, confirms outcomes, and scales with you-so your space operates like a professional environment, hygienic, protected, and regulation-compliant.